|

|

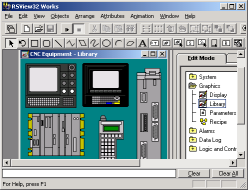

Software Used: |

|

RSView 32 Works with Windows XP (SP2) |

|

|

Course Description: |

|

In this course, we will look at real world examples of RSView screens from your plant to see how they work on your own systems. Students who attend this course will then learn how to develop professional screens utilizing th graphics and animation features available in RSView, and set up communications between the RSView terminal and the PLC. During the development, students will also learn how to plan a project, set up the screen layouts (including navigation), and deploy the project for the operators to use. |

|

|

Prerequisites: |

|

We highly recommend that students of this course first attend a maintenance and troubleshooting course, or be familiar with program and data files in the PLC. Students must also be comfortable working in a Windows environment. |

|

|

Course Objectives: |

|

At the completion of this course, students will be able to:

Demonstrate an understanding of PLC-5 data tables

Demonstrate an understanding of RSView commands, screens and menus

Successfully set up communications between RSView software and a PLC

Set up and navigate RSView screens

Demonstrate the ability to use text and graphic objects, binary objects and data objects

Demonstrate an ability to troubleshoot programs and trace data between RSView and a PLC

Demonstrate an understanding of trending and utilize trending in a simulated application |

|

|

Outline: |

|

Review of PLC-5 data tables

Introduction to the screens and menus used to navigate through RSView

Communication between RSView and a PLC

Adding screens to RSView

Screen to screen navigation

Using text and graphic objects

Binary objects (such as pushbuttons and lights

Data objects (using analog values)

Animating objects (such as rotation, color, and position)

Troubleshooting (Tracing data between RSView and the PLC)

Trending |

|

<< Back to Courses Page

| Return to the top ^^ | Printable Version

| |

|