|

|

Software Used: |

|

RSLogix 500 or AI 500 software depending on client\'s requirements. |

|

|

Course Description: |

|

Students who attend this course will learn how to set up communication with the processor, go online with the project, and locate an output that will not energize such as a solenoid or relay. We use your plant programs as real world examples for practice, then load simulation programs into our workstations. Participants will learn how to trace an output through the program to determine the root cause of a problem, and find out why the PLC is not calling for the output to energize. During this process, students will learn about instructions in the PLC, and other troubleshooting tools that are available to minimize downtime. |

|

|

Prerequisites: |

|

Students must be comfortable operating in a Microsoft Windows environment |

|

|

Course Objectives: |

|

At the completion of this course, students will be able to:

Demonstrate the ability to set up communications between the MicroLogix 1000 and the computer

Demonstrate the ability to edit ladder logic using the appropriate software

Identify and repair system faults

Troubleshoot and repair hardware faults

Create and use data tables

Demonstrate correct file structure techniques

Correctly perform backup and restore procedures

Demonstrate the ability to use search routines to locate items within a project

Demonstrate the ability to use software troubleshooting tools |

|

|

Outline: |

|

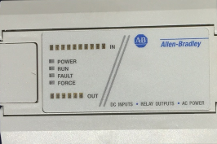

MicroLogix hardware

Communication protocols

Addressing

Utilizing data tables

Program file structure

Program documentation

Navigating through a project

Utilize troubleshooting tools (available in RSLogix)

Troubleshooting practice

Forcing I/O

Comparing Projects |

|

<< Back to Courses Page

| Return to the top ^^ | Printable Version

| |

|